Welded Wire Mesh Gabions & Woven Wire Gabions

Gabion Mattress, Boxes and Rockfall Netting Exporter

Sack Type Gabions

Sack Gabions are double twist hexagonal wire mesh units consisting of a single mesh panel laced to form a cylindrical unit. The wire used in the manufacture of the sack gabion is heavily zinc coated soft temper steel.

Sack Gabions are double twist hexagonal wire mesh units consisting of a single mesh panel laced to form a cylindrical unit. The wire used in the manufacture of the sack gabion is heavily zinc coated soft temper steel.

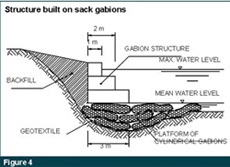

Wire mesh sack gabions are filled with rock at the project site to form flexible, permeable, monolithic structures used for emergency and river training works where local conditions require fast installation or where the water does not allow for easy access to the site and where underwater installation is necessary.

How to use: Sack gabions filled with stones are used in river control and various emergency works. Sack gabions are supplied with steel reinforcing wires inserted during the manufacturing process to facilitate closing during installation.

Treatment: Wire for making of sack gabion is electro galvanized.

Dimensions and sizes of galvanized sack gabions can be customized.

Features of Sack Type Gabions:

(1) Economic and useful: What we need to do is just put the stones into the cage without special skills.

(2) It is convenient to transport as it can be transported folded, assembly on site.

(3) It has a strong resistance to natural destruction and poor weather.

(4) It can withstand large-scale deformation, and does not collapse.

(5) Some plants can grow in the gap among the rocks, and it can melt with the natural environment surrounding together.

(6) And it has good permeability, which can prevent the damage caused by fluid static.

Uses of Sack Gabions:

Uses of Sack Gabions:

Sack Gabions can be widely used in highways, railways, protecting hillside, hillside greening, well and alley fence, building and breeding, zoo fence, greening fence, hillside net cage, flood fighting net cage, revet fence, control and guide the direction of river, spillway and diversion channel, rock fall protection, prevent soil and water from flowing, beach protecting project, protection of the bridge, solid structures defense project, retaining wall, and port project, etc.

Material Delivery

Sack Gabions are manufactured with all components mechanically connected at the production facility. All Sack Gabions are supplied in the collapsed form, folded and bundled. The bundles are compressed and strapped together at the factory for easy shipping and handling. Lacing wire is supplied in coils. Ring fasteners are shipped in boxes which must be stored in a dry condition.

Assembly

The folded sack gabions units shall be taken out from the bundle and placed on a hard flat surface. They shall be opened, unfolded and pressed out to their original shape ready for assembly.

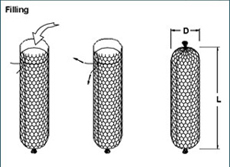

Installation and Filling

Rocks for Sack Gabions may be produced by any suitable quarrying method, and by the use of any device that yields the required sizes within the gradation limits chosen.Rocks shall be hard, angular to round, durable and of such quality that they shall not disintegrate on exposure to water or weathering during the life of the structure. Rocks shall range between 100 mm and 200 mm. The range in sizes may allow for a variation of 5% oversize and/or 5% undersize rock, provided it is not placed on the exposed surface .In all cases, the oversize rock shall not be larger than 250 mm, and the undersize rock shall not be smaller than 80 mm.

Rocks for Sack Gabions may be produced by any suitable quarrying method, and by the use of any device that yields the required sizes within the gradation limits chosen.Rocks shall be hard, angular to round, durable and of such quality that they shall not disintegrate on exposure to water or weathering during the life of the structure. Rocks shall range between 100 mm and 200 mm. The range in sizes may allow for a variation of 5% oversize and/or 5% undersize rock, provided it is not placed on the exposed surface .In all cases, the oversize rock shall not be larger than 250 mm, and the undersize rock shall not be smaller than 80 mm.

Rock shall be placed from the open end of the cylindrical shaped gabion. Once the Sack Gabion has been filled satisfactory, the ends of the top spiral wire are pulled tight, twisted and looped onto itself. Care shall be taken when placing the stone to avoid damaging the wire coating. Hand manipulation of the rock may be necessary to minimise voids and achieve a maximum density of the rock in the Sack Gabion.

Email: sales@weldedwiregabions.com URL: https://www.weldedwiregabions.com